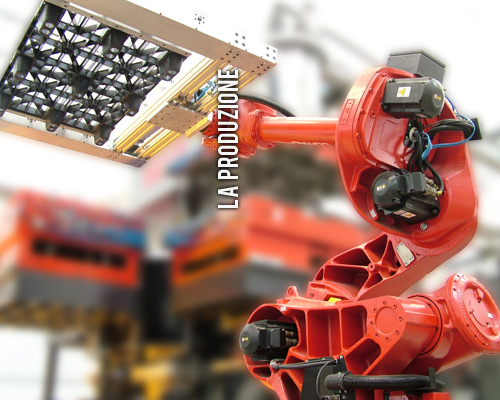

THE PRODUCTION

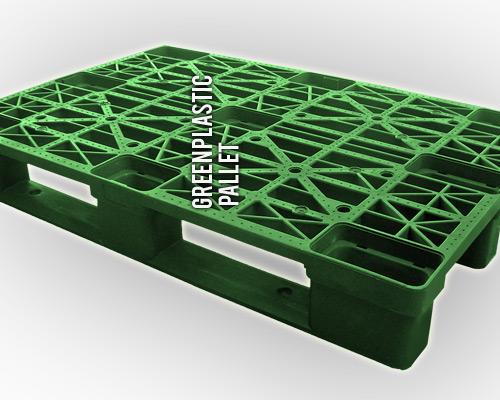

Green process 4 ENVIRONMENTALLY FIRENDLY green products

Please install the Flash Plugin

Thanks to the innovative new generation molding equipment, only recycled plastics may be used, printing simultaneously and with short production cycles articles of different shape and size, reducing energy consumption as well.

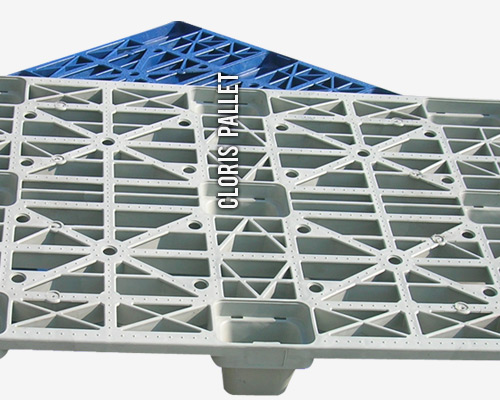

This environmentally friendly and sustainable system is based on three main principles: closed production cycle, conservation of natural resources, materials that can be reused and recycled within the same process.

The operation is based on very low pressure injection with more injection points though wide passage spruing nozzles. This principle makes it possible to transform and homogenize plastic by means of specially designed single-screw extruders. Compounds have a good thermal stability, low withdrawal coefficient and are not hygroscopic.

Printed products can be reused at the end of their lifetime by grinding them with normal mills and balancing them into the basic compounds.

The production lines allow to obtain industrial products with excellent quality and performance, as well as to process without distinction different types of plastics.

Furthermore, this technology has made it possible to industrialize an innovative and 100% environmentally sustainable production process, which does not consume any natural resources and does not emit greenhouse gases into the atmosphere thanks to the possibility to recycle an already recycled product and thus to generate a closed loop process.

Facebook

Facebook Google Plus

Google Plus Twitter

Twitter Youtube

Youtube