History

Cloris, history

1. Pallet, the origins

2. Development

3. Standard used

4. Phytosanitary regulations

5. Pallet worldwide

6. New generation pallets. Plastic pallets

1. Pallet, the origins

The pallet application for civil matters has been inspired by the work of the U.S. military during World War II. Handling and shipping goods to Europe was greatly simplified thanks to the use of pallets and of mechanical equipment; soon pallets started to have a civil use too, being used as a lifting platform support for forklifts.

![]() Back to top

Back to top

2. Development

Based on these assumptions, pallets quickly became a common use asset, tank to the benefits they could offer, from sparing time in handling and shipping goods, as well as isolation for the transported goods from the ground below, thus reducing damages caused by the presence of humid or wet surfaces.

The development of pallet consists in the use of different materials for its manufacturing, such as plastic, metal and compressed chipboard.

The use of this materials gave pallets different positioning, according to specific uses: metal for handling of very heavy loads, wooden chipboard for cheaper production and single shipment use, and plastic, now booming, which ensures longer life of the pallets, overcomes all sanitation problems especially in the farming, food and pharmaceutical industry, allows cross-border shipments without any fumigation certificate and grants low cost single shipment products.

![]() Back to top

Back to top

3. Standard used

Since its birth, when pallet size was left to the discretion of individual users, a standardization became soon necessary and led to today’s situation: pallets for overall purposes with standard features.

![]() Back to top

Back to top

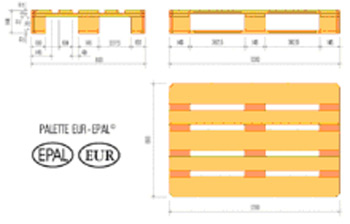

European pallet

Technical specifications of the EUR pallet

In Europe two classical sizes have been established 800x1200 mm, soon defined as "EUR" pallet and 1000x1200 mm, as industrial pallet. The height from the ground remains the same, as well as the presence of three lower crosspieces with thickness of 22 mm. This “four-way” pallet can be forked on all sides both by forklifts and pallet trucks. Standardization also sets the basis for interchange, as nowadays almost all major retail chains interchange pallets, thereby avoiding problems linked to pallets to be returned back, once the shipment has been completed.

"EUR" pallet with load ready for handling

![]() Back to top

Back to top

4. Phytosanitary Regulations

Since wood is a potential vehicle for harmful organisms to the vegetable world, on May 5th, 2000, the EU issued Directive No. 2000/29, thereby defining the specific requirements for wooden pallet circulation among the various nations. It has been made mandatory to submit wood to a preventive treatment, defined “fumigation”, through the use of chemical products based on methyl bromide, or alternatively to heat treatment, consisting on wood being treated in special cells, called driers. These two methods are equivalent and both recognized as valid for the purposes of Directive ISPM 15 Fao to eliminate parasites that can bring serious damage to forests. Such treatment is proved by the presence on the pallet of special marking.

On the contrary, plastic pallets do not need any chemical or heat treatment for trans-boundary shipments.

![]() Back to top

Back to top

5. Pallet worldwide

Various world standards are different from the “EUR” size 800x1200 m. In the U.S. the standard size is 40x48 inches (corresponding to 1000x1200 mm), while in Asia the size used is 1100x1100 mm.

![]() Back to top

Back to top

6. New generation pallets. Plastic pallets.

A new era is starting about the use of pallets in a modern way. The wooden pallet entered the market in the 50’s, transforming the system of cargo handling for over 50 years.

Over time the wooden pallet has not undergone big technical innovations, except for its standardization. As to its essence, it once was wooden pallet and wooden pallet is still nowadays.

Today, within the advanced systems for cargo handling, pallets have become an instrumental asset not to dispose of, essential for the management of integrated logistics applied throughout the supply chain.

Plastic pallet has been created on the basis of recent phytosanitary regulations for intercontinental handling of goods, in order to meet the changing environmental regulations on packing, the need to track and trace goods in specific product sectors and the growing demand for optimization of logistics.

Thanks to its manufacturing process, new generation plastic pallets can easily be equipped with RFID microchips, which allow to track and map the goods in real time with excellent benefits in terms of cost and time, optimizing goods handling.

The main benefits deriving from the use of plastic pallets are freedom from maintenance, inalterability over time, possibility to contain anti-slip inserts, significantly higher duration (8-10 times the average life of a wooden pallet) , immunity from humidity, absorption of vibrations and shocks, possibility of being completely recycled within the same production processes.

![]() Back to top

Back to top

Stackable

Strong

Cleaning

Security

Facebook

Facebook Google Plus

Google Plus Twitter

Twitter Youtube

Youtube